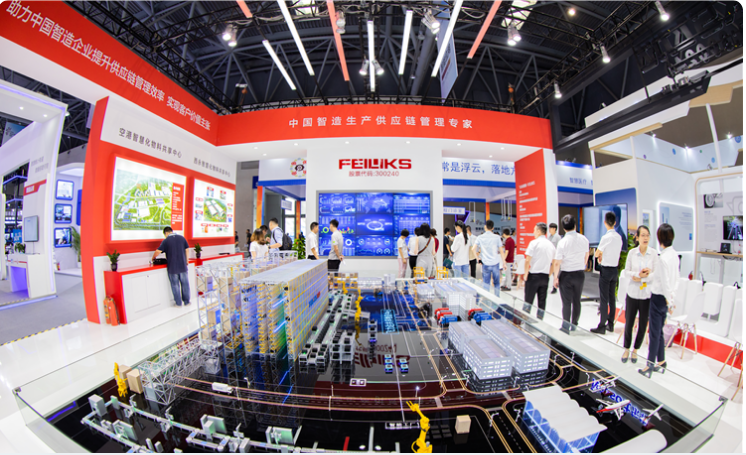

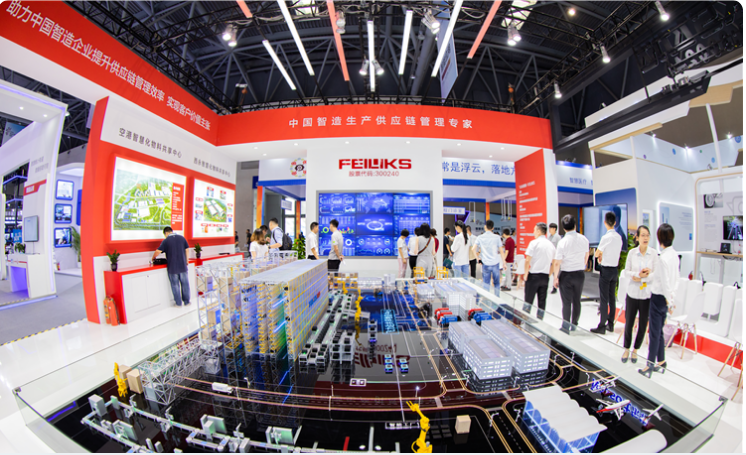

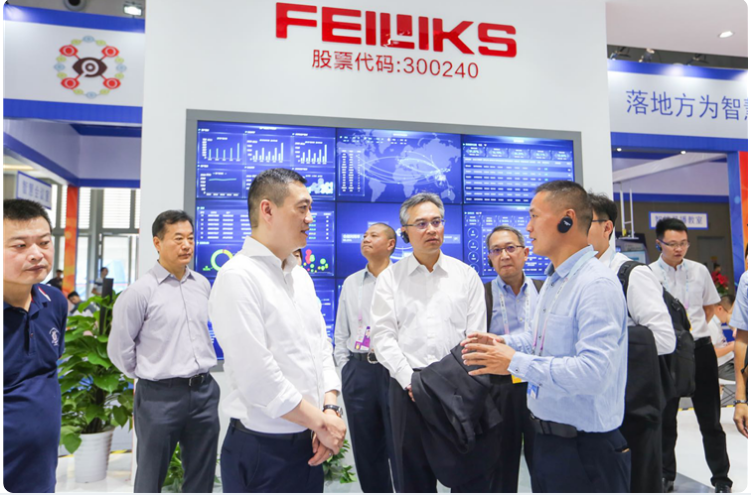

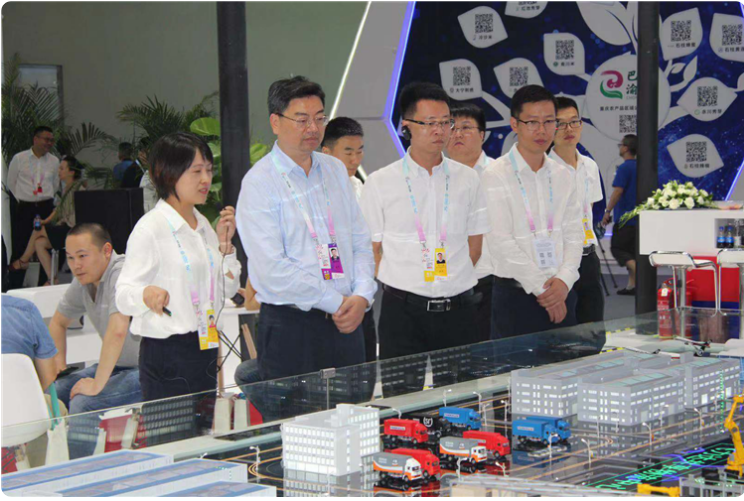

In the industrial 4.0 era, the global manufacturing industry is accelerating towards digitalization and intellectualization, and the intelligent logistics supply chain is prospering. On August 27, in the Feiliks exhibition hall of the Smart China Expo, multi-layered automated warehouses, transportation systems, robotic palletizers and depalletizers, AGV, 5G driverless distribution vehicles, supply chain control towers and other products were displayed. A brand-new sandbox in collaboration with smart supply chain, and smart management Kanban attracted many citizens on the sight.

As a technology-driven expert of management of intelligent supply chain, Feiliks is a 5A-class listed logistics enterprise and engaged in high-end manufacturing industries such as IT, communications, automotive and precision instruments, focusing on providing customers with integrated logistics services such as freight forwarding, warehousing and transportation, supply chain finance, supply chain solutions, etc. Chongqing Feiliks Supply Chain Management Co., Ltd. is a comprehensive supply chain management company jointly established by Feiliks and Chongqing Light Industry & Textile Group. It has established “Intelligent Supply Chain Sharing Center” in the bonded area of bonded port airport and Xiyong bonded area. Specifically, the “Intelligent Supply Chain Sharing Center” in the airport has been put into operation and the one in Xiyong will be put into operation early next year.

Current modern logistics trend lies in less-manned or unmanned warehousing, which not only saves space for enterprises, but also improves efficiency and accuracy. For a long time, China’s international freight forwarders have been working with ships and goods, and their business scope is limited to space booking, customs clearance, transshipment and other simple service links. Their services are “according to the routine” and “too observant of conventional standards” in other words. As a listed company rooted in the supply chain system, Feiliks not only integrates modern service enterprises such as international trade, bonded marketing, supply chain management, warehousing logistics, e-commerce and multimodal transport, but also strives to build a “smart supply chain sharing center” to form a new business model.

Geng Hao, the president of Feiliks, told reporters, “At present, our customers are from electronics, automotive, intelligent manufacturing and other industries, with hundreds of Top 500 enterprises in the world involved. In recent years, with continuous development of assembly line system in production and manufacturing, there is only a narrow development space for enterprises. Therefore, it is important to exchange upstream and downstream enterprise data and achieve operational connectivity, which cannot only to improve manufacturing enterprises’ efficiency, but also to save costs. Last year, we decided to build an intelligent warehouse in a free trade zone, utilize new technologies such as intelligent warehouse, unmanned truck, AGV, air corridor and so on, and provide integrated supply chain for ODM enterprises. According data analysis in several months after production, we reached the expected value and also helped manufacturing enterprises improve their efficiency.”

In the free trade zone, Feiliks Automated Multi-layered Warehouse, covering an area of 3,000 square meters, has been built and put into use. In addition to 12 lanes and 12 palletizers, 10 AGV carriers, 2 image-identifiable lines, software and hardware with automatic control, and other advanced fully-automated equipment are equipped.

It is known that Feiliks will also introduce unmanned forklifts in the Chongqing project one after another, streamlining manpower in receiving and dispatching operations and making overhead working safer; robotic palletizers and depalletizers can accomplish requirements of multiple production lines with excellent accuracy, speed and high efficiency and stability; AGV and RFID will be put into use to relieve manpower stress between warehouse side and client side; and 5G unmanned distribution vehicles will link unmanned distribution and information flow between shared logistics center and customers.

Sheng Huawei, general manager of Feiliks’ Engineering and Technology Department, said, “Storage boxes are automatically on the move. So, pickers only need to scan the barcode of storage boxes with RF rings. Then the block to be stored will be displayed on the computer, and so be the number of goods and plates to be selected. The supply chain management tower at the other side of LCD screen can also control the whole process of arrival time, customs clearance, transportation, warehousing, inventory and production line through the needs of customers, so as to provide efficient improvement and countermeasures for enterprises.”

It is reported that with the use of automated multi-layered warehouses, high-level warehouse rationalization, access automation, easy operation, and improved utilization of space can be realized; through computer network technology, the storage operations and tracking management system can achieve real-time quality tracking management, real-time production variety tracking management and real-time distribution tracking management, and realize online integrated operation; seamless connection of production, storage and distribution integrates automated multi-layered warehouses with the production system of the whole enterprise, forming its complete and rational logistics system, and improving its production management. Such measures not only conform to the trend of “intelligent production” era, but also comprehensively improve the company logistics capabilities and management, thus providing customers with better service!

Geng Hao, president of Feiliks, said, “As the logistics supply chain is an important supporting function of manufacturing enterprises and the basic service function of local governments, Feiliks has been following the pace of development of China’s manufacturing industry. Since we settled in Chongqing ten years ago, we have taken root in local development and made contributions to the development of electronic manufacturing industry there. Last year, Feiliks import and export business in Chongqing reached nearly US$2 billion, and the scale of its enterprises has been expanding year by year. In addition to functional connectivity of hardware, the connectivity of software and data is of more importance. Now that our automated warehouse has been fully automated, we will further promote the development of intelligent supply chain in the future. By connecting the upstream and downstream data of the supply chain, we can alert enterprises, make plans and predict the future, so as to further improve efficiency and create value for manufacturing enterprises!”

At the beginning of next year, Feiliks’ project located in Southwest Supply Chain Base in Xiyong will be put into use. The base mainly adopts advanced information technology such as intelligent manufacturing and Internet of Things to build regional cloud service platform of electronic material storage and distribution, and further Feiliks global electronic material distribution center and Southwest Land Transport and Distribution Base. The base will lay the foundation for the construction of Intelligent Warehousing Logistics in Xiyong Bonded Area and Intelligent Integrated Comprehensive Bonded Area.

In the future, Feiliks will also be a shared supply chain center in Chongqing’s non-bonded areas, introducing more manufacturing enterprises for domestic market. By integrating the back-end supply chains of different enterprises, Feiliks will focus on production lines, improve productivity and efficiency, and provide guaranteed infrastructure for more manufacturing enterprises to settle in Chongqing.